Detailed Parameters of Joints in Each Series:

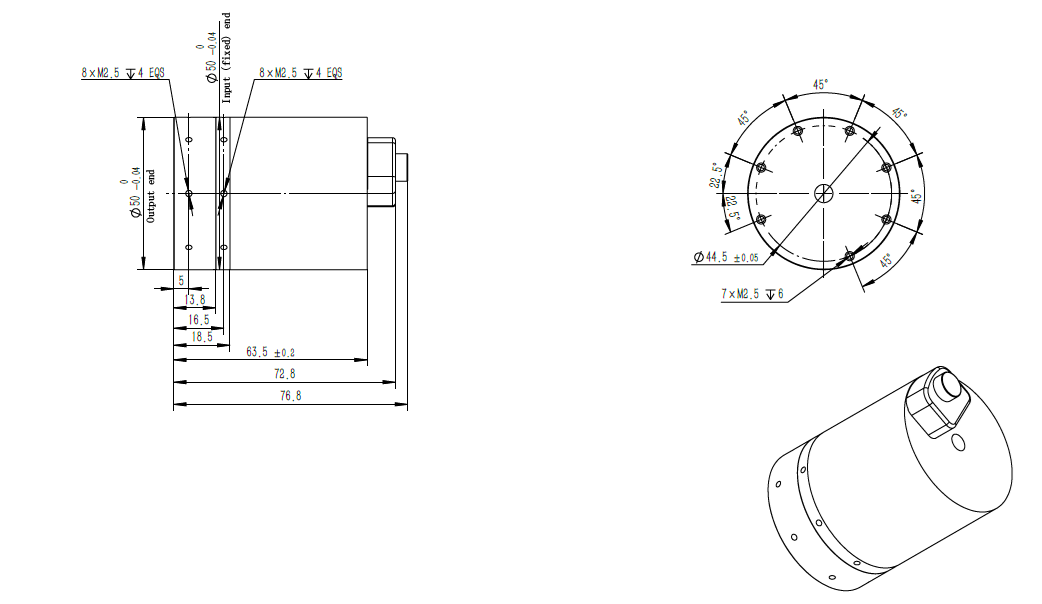

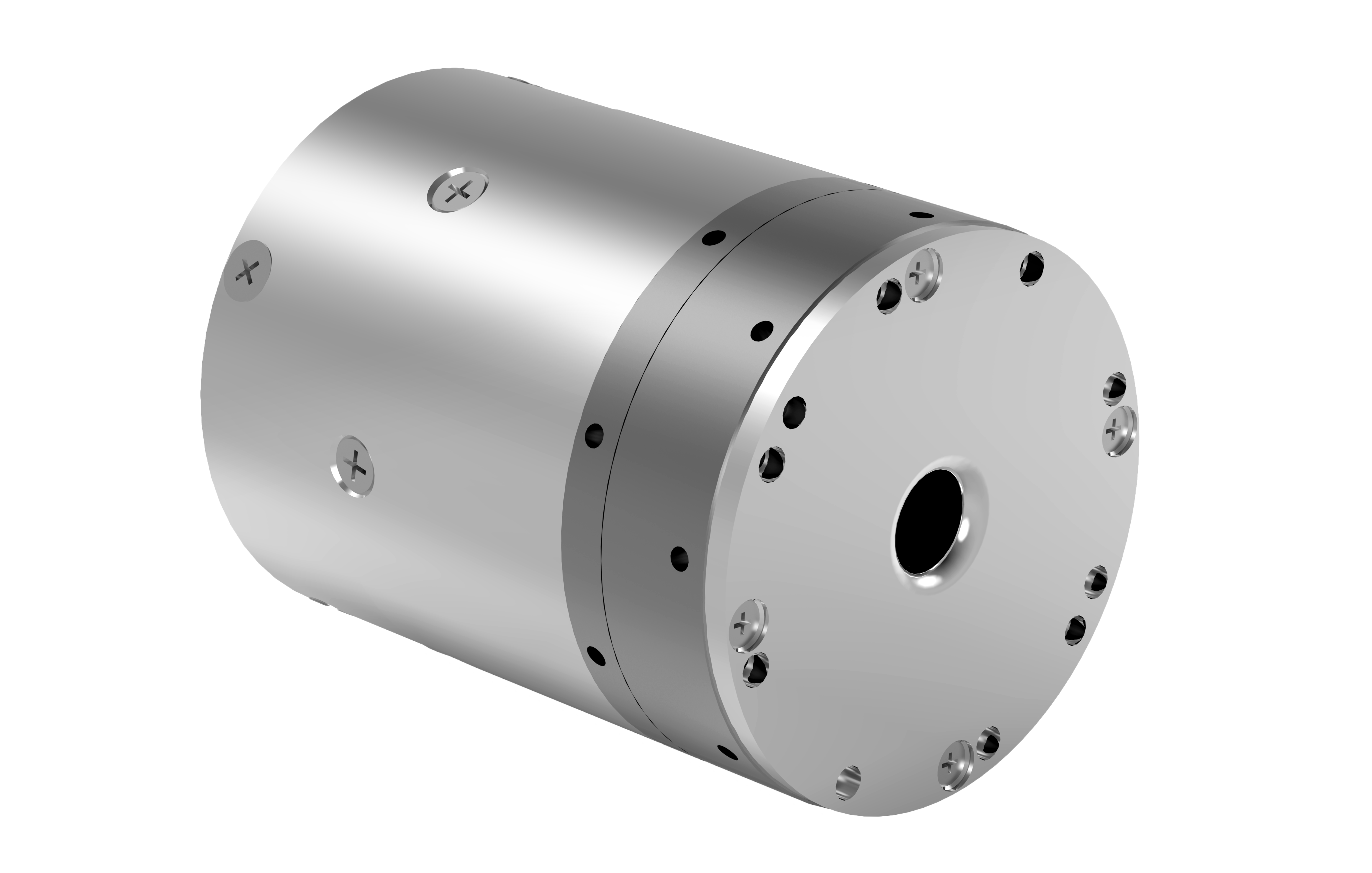

WHJ10 Series Specifications Model: WHJ10-M-D50-80-B

Illustration

Performance parameters

| Parameter | Value |

|---|---|

| Reduction ratio | 80 |

| Weight | 455 g |

| Diameter of reducer mm | 50 |

| Size (D × L mm) | 50 * 73 |

| Rated torque N.m | 10 |

| Maximum torque density | 67.4 |

| Repeatability | ±15 arc-seconds |

| Peak speed (RPM) | 37.5 (24V) / 75 (48V) |

| Moment of inertia (kg*m^2) | 1.13*10^-5 |

| Hollow aperture | 8 mm |

| Working temperature | 0 to 50°C |

| Rated power | 63 W |

| Rated voltage | 24 V / 48 V |

| Rated current | 2.6 A (24 V) / 1.3 A (48 V) |

| Type of brake | Latch brake |

| Incremental encoder | 16 bits |

| Absolute position encoder | 18 bits |

| Communication interface | CANFD |

| Examples of scenarios | Lightweight robotic arm, surgical robot, neck joint and wrist joint of humanoid robot, Service robot, precision turntable, etc. |

When operating under high loads and high speeds, the joint module generates regenerative braking energy. An external "Power Discharge Module" (see Power Bleeding Module) is required to prevent errors and shutdowns due to excessive bus voltage caused by regenerative energy feedback leading to a surge in the power supply voltage.

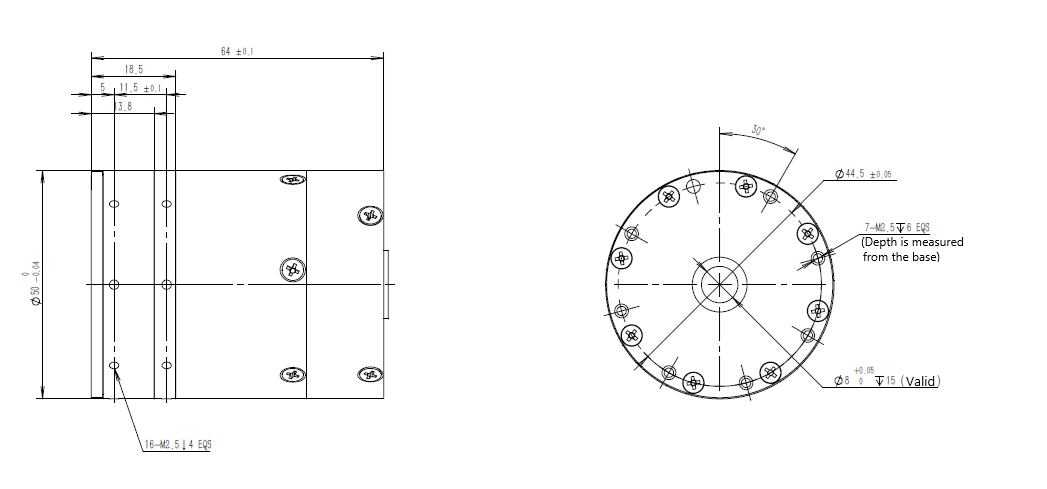

Detailed dimensions

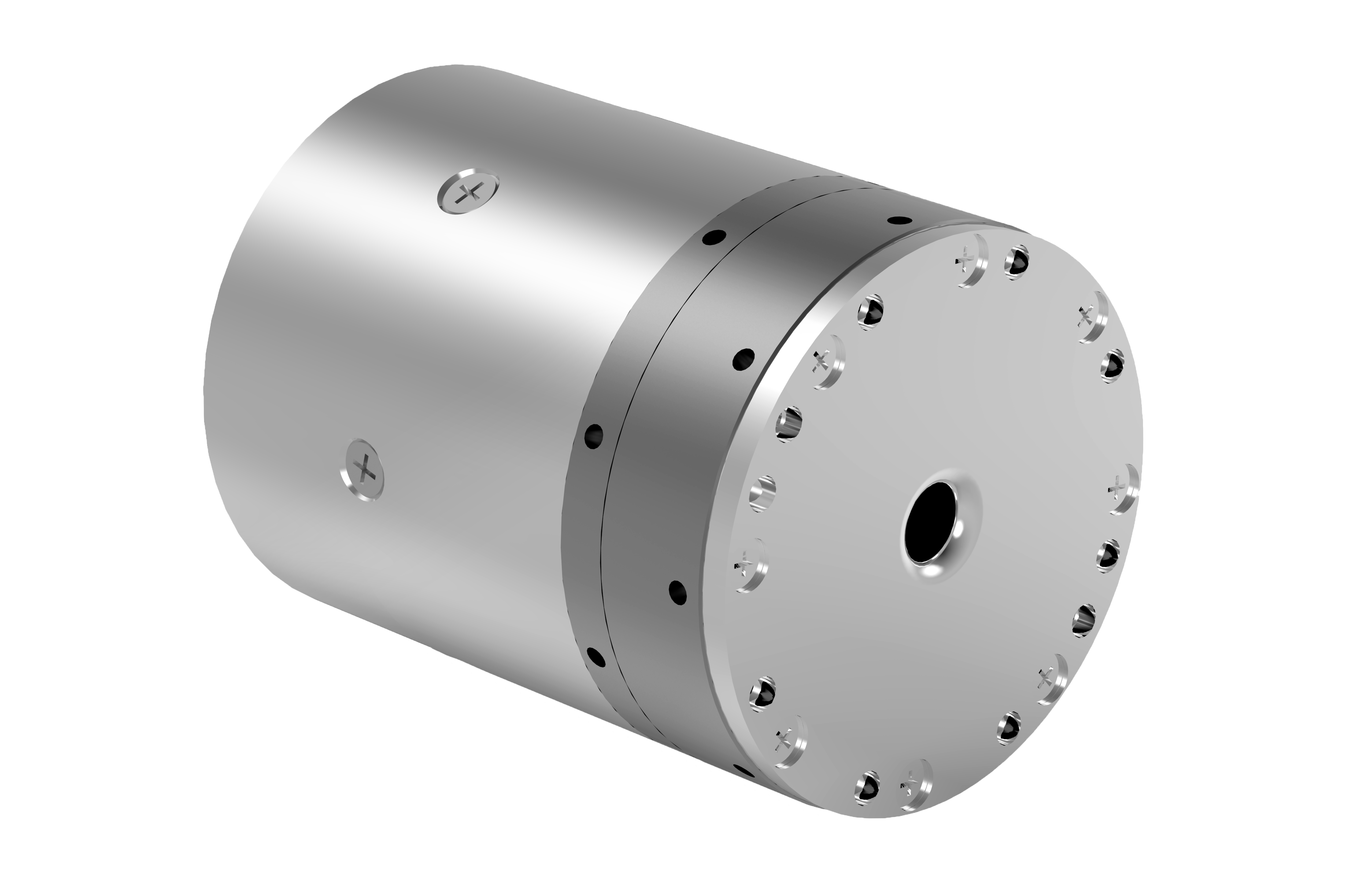

Model: WHJ10-M-D50-80-N

Illustration

Performance parameters

| Parameter | Value |

|---|---|

| Reduction ratio | 80 |

| Weight | 445 g |

| Diameter of reducer mm | 50 |

| Size (D × L mm) | 50 * 64 |

| Rated torque N.m | 10 |

| Maximum torque density | 75 |

| Repeatability | ±15 arc-seconds |

| Peak speed (RPM) | 37.5 |

| Moment of inertia (kg*m^2) | 1.09*10^-5 |

| Hollow aperture | 8 mm |

| Working temperature | 0 to 50°C |

| Rated power | 63 W |

| Rated voltage | 24 V |

| Rated current | 2.6 A |

| Type of brake | Soft brake |

| Incremental encoder | 16 bits |

| Absolute position encoder | 18 bits |

| Communication interface | CANFD |

| Examples of scenarios | Lightweight robotic arm, neck joint of humanoid robot, intelligent travel products, etc. |

When operating under high loads and high speeds, the joint module generates regenerative braking energy. An external "Power Discharge Module" (see Power Bleeding Module) is required to prevent errors and shutdowns due to excessive bus voltage caused by regenerative energy feedback leading to a surge in the power supply voltage.

Detailed dimensions