Python:

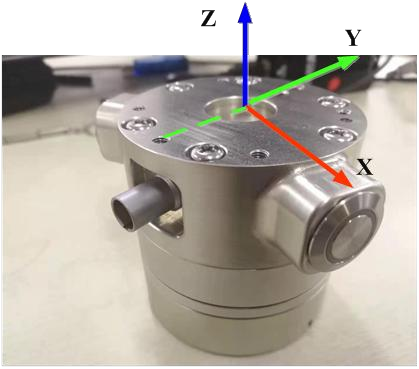

End 6-DoF Force Sensor ConfigurationForce The 6-DoF force version of the RealMan robotic arm is equipped with an integrated 6-DoF force sensor at the end effector, eliminating the need for external wiring and allowing the user to manipulate the 6-DoF force and obtain 6-DoF force data directly through the protocol. As shown in the image below, the Z-axis of the 6-DoF force is directly above, and the Y-axis of the 6-DoF force is in the opposite direction of the aviation connector, with the frame following the right-hand rule. When the robotic arm is in the zero position, the tool frame is aligned with the 6-DoF force frame.

Additionally, the 6-DoF force sensor has a rated force of 200 N, a rated torque of 7 N.m, an overload capacity of 300FS, an operating temperature range of 5°C to 80°C, and an accuracy of 0.5FS. During use, it is important to pay attention to the operational requirements to prevent damage to the 6-DoF force sensor. Here is the 6-DoF force frame:

This interface is used to get and configure the end force sensor. The following is a detailed description of the member functions of the end 6-DoF force sensor configuration Force, including the method prototype, parameter description, return value, and usage demo.

Get the force data of the 6-DoF force sensor rm_get_force_data()

Get the current force and torque data obtained from the 6-DoF force sensor, including Fx, Fy, Fz, Mx, My, and Mz.

- Method prototype:

rm_get_force_data(self) -> tuple[int, dict[str, any]]:- Return value:

tuple[int, dict[str,any]]: a tuple containing two elements.

- int: state codes executed by functions.

0 represents success. For other error codes, please refer to the API2 Error Codes.

- 6-DoF force data dictionary

| Parameter | Type | Description |

|---|---|---|

rm_force_data_t | dict[str, any] | 6-DoF force data dictionary, key: field name of rm_force_data_t |

- Usage demo

from Robotic_Arm.rm_robot_interface import *

# Instantiate the RoboticArm class

arm = RoboticArm(rm_thread_mode_e.RM_TRIPLE_MODE_E)

# Create the robotic arm connection and print the connection ID

handle = arm.rm_create_robot_arm("192.168.1.18", 8080)

print(handle.id)

print(arm.rm_get_force_data())

arm.rm_delete_robot_arm()Calibrate the zero position under the current state rm_clear_force_data()

Clear the 6-DoF force data and calibrate the zero position under the current state.

- Method prototype:

rm_clear_force_data(self) -> int:- Return value: State codes executed by functions:

0 represents success. For other error codes, please refer to the API2 Error Codes.

- Usage demo

from Robotic_Arm.rm_robot_interface import *

# Instantiate the RoboticArm class

arm = RoboticArm(rm_thread_mode_e.RM_TRIPLE_MODE_E)

# Create the robotic arm connection and print the connection ID

handle = arm.rm_create_robot_arm("192.168.1.18", 8080)

print(handle.id)

print(arm.rm_clear_force_data())

arm.rm_delete_robot_arm()Set the 6-DoF force center of gravity parameters automatically rm_set_force_sensor()

Set the 6-DoF force center of gravity parameters. After reinstalling the 6-DoF force sensor, the initial force and center of gravity acting on the 6-DoF force must be recalculated. Get 6-DoF force data at different orientations to calculate the center of gravity position. After this command is issued, the robotic arm moves to each calibration point at a fixed speed.

Take the RM65 robotic arm as an example, the joint angles for the four calibration points are as follows:

Point 1 joint angle: {0,0,-60,0,60,0}

Point 2 joint angle: {0,0,-60,0,-30,0}

Point 3 joint angle: {0,0,-60,0,-30,180}

Point 4 joint angle: {0,0,-60,0,-120,0}

Method prototype:

rm_set_force_sensor(self, block: bool) -> int:- Parameter description:

| Parameter | Type | Description |

|---|---|---|

block | bool | true: blocking mode, return after the calibration is complete, false: non-blocking mode, immediately return after sending commands |

- Return value: State codes executed by functions:

0 represents success. For other error codes, please refer to the API2 Error Codes.

- Usage demo

from Robotic_Arm.rm_robot_interface import *

# Instantiate the RoboticArm class

arm = RoboticArm(rm_thread_mode_e.RM_TRIPLE_MODE_E)

# Create the robotic arm connection and print the connection ID

handle = arm.rm_create_robot_arm("192.168.1.18", 8080)

print(handle.id)

print(arm.rm_set_force_sensor(True))

arm.rm_delete_robot_arm()Calibrate the 6-DoF force data manually rm_manual_set_force()

After reinstalling the 6-DoF force sensor, the initial force and center of gravity acting on the 6-DoF force sensor must be recalculated. This manual calibration is applicable to narrow working spaces to prevent the robotic arm from colliding during the automatic calibration. Users can manually select four points to issue commands. Once all four points are set, the robotic arm will automatically move toward the user-defined target, and the 6-DoF force center of gravity will be calculated during this movement.

WARNING

The commands for four points must be issued in sequence. Once point 4 is set, the robotic arm will automatically calculate the center of gravity.

- Method prototype:

rm_manual_set_force(self, point_num: int, joint: list[float], block: bool) -> int:- Parameter description:

| Parameter | Type | Description |

|---|---|---|

point_num | int | Point numbers 1−4 |

joint | list[float] | Joint angle, in ° |

block | bool | true: blocking mode, return after the calibration is complete, false: non-blocking mode, immediately return after sending commands |

- Return value: State codes executed by functions:

0 represents success. For other error codes, please refer to the API2 Error Codes.

- Usage demo

from Robotic_Arm.rm_robot_interface import *

import time

# Instantiate the RoboticArm class

arm = RoboticArm(rm_thread_mode_e.RM_TRIPLE_MODE_E)

# Create the robotic arm connection and print the connection ID

handle = arm.rm_create_robot_arm("192.168.1.18", 8080)

print(handle.id)

set_force_data = [({'point_num': 1, 'joint': [0, 0, -60, 0, 60, 0], 'block': True},

{'point_num': 2, 'joint': [0, 0, -60, 0, -30, 0], 'block': True},

{'point_num': 3, 'joint': [0, 0, -60, 0, -30, 180], 'block': True},

{'point_num': 4, 'joint': [0, 0, -60, 0, -120, 0], 'block': True})]

print(arm.rm_manual_set_force(**set_force_data[0]))

time.sleep(1)

print(arm.rm_manual_set_force(**set_force_data[1]))

time.sleep(1)

print(arm.rm_manual_set_force(**set_force_data[2]))

time.sleep(1)

print(arm.rm_manual_set_force(**set_force_data[3]))

time.sleep(1)

arm.rm_delete_robot_arm()Stop calibrating the force sensor center of gravityrm_stop_set_force_sensor()

- Method prototype:

rm_stop_set_force_sensor(self) -> int:- Return value: State codes executed by functions:

0 represents success. For other error codes, please refer to the API2 Error Codes.

- Usage demo

from Robotic_Arm.rm_robot_interface import *

# Instantiate the RoboticArm class

arm = RoboticArm(rm_thread_mode_e.RM_TRIPLE_MODE_E)

# Create the robotic arm connection and print the connection ID

handle = arm.rm_create_robot_arm("192.168.1.18", 8080)

print(handle.id)

print(arm.rm_stop_set_force_sensor())

arm.rm_delete_robot_arm()