Demo (C, C++):

Usage Demo of ModbusRTU 1. Project introduction

This project demonstrates how to configure the ModbusRTU mode of RS485 communication port and perform read/write operations with connected peripheral devices via the interface. The operation flow is as follows:

It configures the ModbusRTU mode of the communication port, writes single coil data, reads single coil data, writes a single register, reads holding registers, and closes the communication port in ModbusRTU mode.

It is built with CMake and utilizes the C language development package for the robotic arm provided by RealMan.

2. Code structure

RMDemo_ModbusRTU

├── build # Output directory generated by CMake build (Makefile, build file, etc.)

├── include # Custom header file storage directory

├── Robotic_Arm # RealMan robotic arm secondary development package

│ ├── include

│ │ ├── rm_define.h # Header file of the robotic arm secondary development package, containing defined data types and structures

│ │ └── rm_interface.h # Header file of the robotic arm secondary development package, declaring all operation interfaces of the robotic arm口

│ └── lib

│ ├── api_c.dll # API library for Windows 64bit

│ ├── api_c.lib # API library for Windows 64bit

│ └── libapi_c.so # API library for Linux x86

├── src

│ └── main.c # Main function

├── CMakeLists.txt # Top-level CMake configuration file of the project

├── readme.md # Project description document

├── run.bat # Windows quick run script

└── run.sh # linux quick run script3. Project download

Download RM_API2 locally via the link: development package download. Then, navigate to the RM_API2\Demo\RMDemo_C directory, where you will find RMDemo_ModbusRTU.

4. Environment configuration

Required environment and dependencies for running in Windows and Linux environments:

| Item | Linux | Windows |

|---|---|---|

| System architecture | x86 architecture | - |

| Compiler | GCC 7.5 or higher | MSVC2015 or higher 64bit |

| CMake version | 3.10 or higher | 3.10 or higher |

| Specific dependency | RMAPI Linux version library (located in the Robotic_Arm/lib directory) | RMAPI Windows version library (located in the Robotic_Arm/libdirectory) |

Linux configuration

1. Compiler (GCC) In most Linux distributions, GCC is installed by default, but the version may not be the latest. If a specific version of GCC (such as 7.5 or higher) is required, it can be installed via the package manager. For example, on Ubuntu, you can use the following commands to install or update GCC:

# Check GCC version

gcc --version

sudo apt update

sudo apt install gcc-7 g++-7Note: If the GCC version installed by default on the system meets or exceeds the required version, no additional installation is necessary.

2. CMake CMake can also be installed through the package manager in most Linux distributions. For example, on Ubuntu:

sudo apt update

sudo apt install cmake

# Check CMake version

cmake --versionWindows configuration

Compiler (MSVC2015 or higher): The MSVC (Microsoft Visual C++) compiler is typically installed with Visual Studio. You can install it by following these steps:

- Visit the Visual Studio official website to download and install Visual Studio.

- During installation, select the "Desktop development with C++" workload, which will include the MSVC compiler.

- Select additional components as needed, such as CMake (if not already installed).

- After installation, open the Visual Studio command prompt (available in the start menu) and enter the

clcommand to check if the MSVC compiler is installed successfully.

CMake: If CMake was not included during the Visual Studio installation, you can download and install CMake separately.

- Visit the CMake official website to download the installer for Windows.

- Run the installer and follow the on-screen instructions to complete the installation.

- After installation, add the CMake bin directory to the system's PATH environment variable (this is typically asked during installation).

- Open the command prompt or PowerShell and enter

cmake --versionto check if CMake has been installed successfully.

5. User guide

5.1 Quick run

Follow these steps to quickly run the code:

Configuration of the IP address of the robotic arm: Open the

main.cfile and modify the parameters of therobot_ip_addressin themainfunction to the current IP address of the robotic arm. The default IP address is"192.168.1.18".Cconst char *robot_ip_address = "192.168.1.18"; int robot_port = 8080; rm_robot_handle *robot_handle = rm_create_robot_arm(robot_ip_address, robot_port);Running via linux command line: Navigate to the

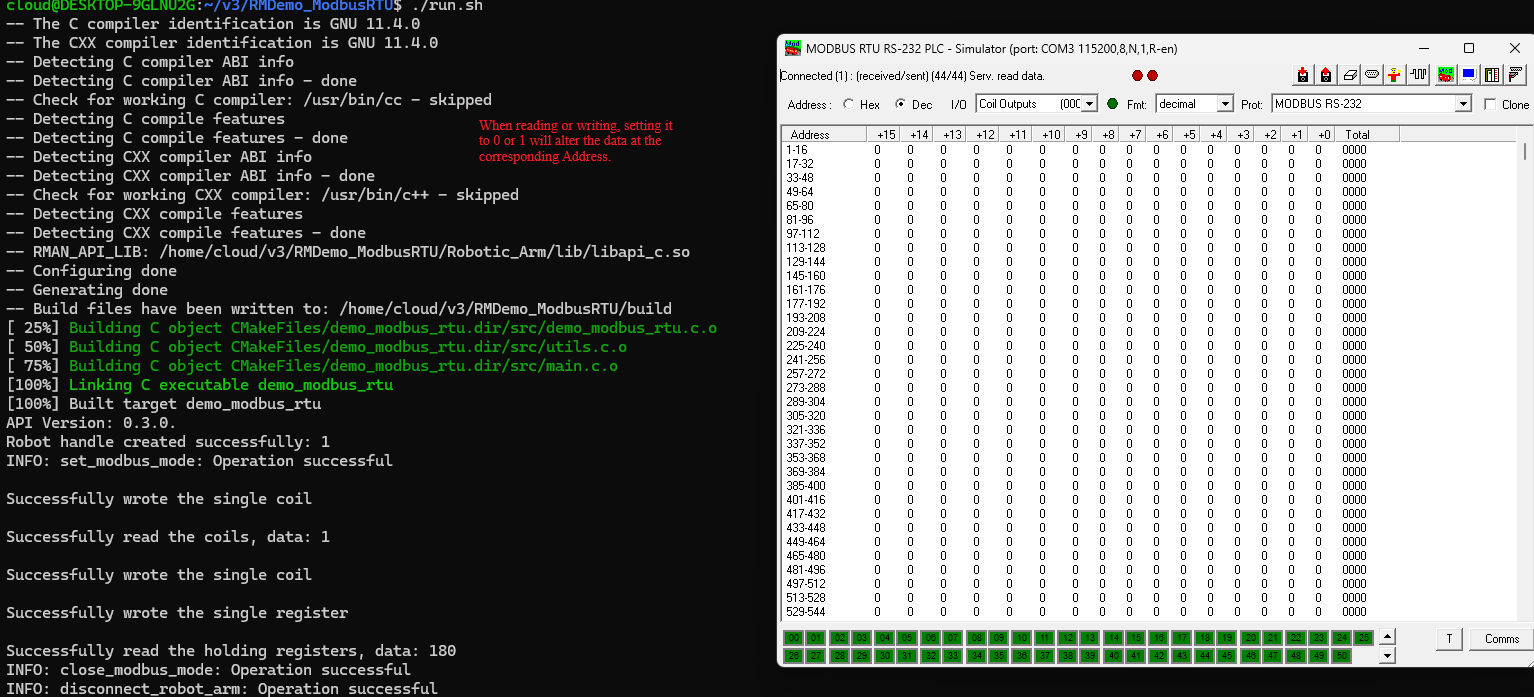

RMDemo_ModbusRTUdirectory in the terminal, and enter the following command to run the C program:bashchmod +x run.sh ./run.shThe running result is as follows:

Refer to the running results on Windows.

Running on Windows: double-click the run.bat script to run The running result is as follows:

Run...

API Version: 1.0.0.

send is: {"command":"get_arm_software_info"}

thread_socket_receive len 315 robot_handle: 1 message:{"Product_version":"RM65-BI","algorithm_info":{"version":"1.4.4"},"command":"arm_software_info","ctrl_info":{"build_time":"2024/08/28 18:36:18","commit_id":"0315333","version":"V1.6.1"},"dynamic_info":{"model_version":"2"},"plan_info":{"build_time":"2024/08/28 18:36:33","commit_id":"166c4a8","version":"V1.6.1"}}

[rm_get_arm_software_info] Product version: RM65-BI

[rm_get_arm_software_info] Algorithm version: 1.4.4

[rm_get_arm_software_info] Ctrl version: V1.6.1

[rm_get_arm_software_info] Ctrl build Time: 2024/08/28 18:36:18

[rm_get_arm_software_info] Dynamic model version: 2

[rm_get_arm_software_info] Plan version: V1.6.1

[rm_get_arm_software_info] Plan build Time: 2024/08/28 18:36:18

send is: {"command":"get_realtime_push"}

thread_socket_receive len 195 robot_handle: 1 message:{"command":"get_realtime_push","custom":{"expand_state":false,"joint_acc":false,"joint_speed":false,"lift_state":false,"tail_end":false},"cycle":5,"enable":true,"ip":"192.168.1.88","port":8089}

[rm_get_realtime_push] cycle parse result: 5

[rm_get_realtime_push] port parse result: 8089

[rm_get_realtime_push] ip parse result: 192.168.1.88

[rm_get_realtime_push] enable parse result: 1

send is: {"command":"get_current_work_frame"}

thread_socket_receive len 74 robot_handle: 1 message:{"frame_name":"World","pose":[0,0,0,0,0,0],"state":"current_work_frame"}

[get_current_work_frame] Work frame Name: World

[get_current_work_frame] Work frame pose: (0.000, 0.000, 0.000, 0.000, 0.000, 0.000)

send is: {"command":"get_current_tool_frame"}

thread_socket_receive len 106 robot_handle: 1 message:{"payload":0,"pose":[0,0,0,0,0,0],"position":[0,0,0],"state":"current_tool_frame","tool_name":"Arm_Tip"}

[get_current_tool_frame] Tool frame Name: Arm_Tip

[get_current_tool_frame] Tool frame pose: (0.000, 0.000, 0.000, 0.000, 0.000, 0.000)

[get_current_tool_frame] Tool frame payloda: 0.000

[get_current_tool_frame] Tool frame position: (0.000, 0.000, 0.000)

send is: {"command":"get_install_pose"}

thread_socket_receive len 41 robot_handle: 1 message:{"pose":[0,0,0],"state":"install_pose"}

[rm_get_install_pose] pose parse result:

0

0

0

send is: {"command":"get_joint_min_pos"}

thread_socket_receive len 87 robot_handle: 1 message:{"min_pos":[-178000,-130000,-135000,-178000,-128000,-360000],"state":"joint_min_pos"}

[rm_get_joint_min_pos] min_pos parse result:

-178000

-130000

-135000

-178000

-128000

-360000

send is: {"command":"get_joint_max_pos"}

thread_socket_receive len 81 robot_handle: 1 message:{"max_pos":[178000,130000,135000,178000,128000,360000],"state":"joint_max_pos"}

[rm_get_joint_max_pos] max_pos parse result:

178000

130000

135000

178000

128000

360000

send is: {"command":"get_joint_max_acc"}

thread_socket_receive len 83 robot_handle: 1 message:{"joint_acc":[100000,100000,100000,100000,100000,100000],"state":"joint_max_acc"}

[rm_get_joint_max_acc] joint_acc parse result:

100000

100000

100000

100000

100000

100000

send is: {"command":"get_joint_max_speed"}

thread_socket_receive len 81 robot_handle: 1 message:{"joint_speed":[30000,30000,37500,37500,37500,37500],"state":"joint_max_speed"}

[rm_get_joint_max_speed] joint_speed parse result:

30000

30000

37500

37500

37500

37500

Robot handle created successfully: 1

send is: {"command":"set_modbus_mode","port":0,"baudrate":115200,"timeout":10}

thread_socket_receive len 48 robot_handle: 1 message:{"command":"set_modbus_mode","set_state":true}

[rm_set_modbus_mode] set_state: true

send is: {"command":"write_single_coil","port":0,"address":0,"data":0,"device":2}

thread_socket_receive len 52 robot_handle: 1 message:{"command":"write_single_coil","write_state":true}

[rm_write_single_coil] write_state: true

send is: {"command":"read_coils","port":0,"address":0,"num":1,"device":2}

thread_socket_receive len 35 robot_handle: 1 message:{"command":"read_coils","data":0}

[rm_read_coils] data parse result: 0

send is: {"command":"write_single_coil","port":0,"address":0,"data":1,"device":2}

thread_socket_receive len 52 robot_handle: 1 message:{"command":"write_single_coil","write_state":true}

[rm_write_single_coil] write_state: true

send is: {"command":"write_single_register","port":0,"address":0,"data":180,"device":2}

thread_socket_receive len 56 robot_handle: 1 message:{"command":"write_single_register","write_state":true}

[rm_write_single_register] write_state: true

send is: {"command":"read_holding_registers","port":0,"address":0,"device":2}

thread_socket_receive len 49 robot_handle: 1 message:{"command":"read_holding_registers","data":180}

[rm_read_holding_registers] data parse result: 180

send is: {"command":"close_modbus_mode","port":0}

thread_socket_receive len 50 robot_handle: 1 message:{"command":"close_modbus_mode","set_state":true}

[rm_close_modbus_mode] set_state: true

Press any key to continue...5.2 Description of key codes

The following are the main functions of the main.c:

Connect the robotic arm

Crm_robot_handle *robot_handle = rm_create_robot_arm(robot_ip_address, robot_port);Connect the robotic arm to the specified IP address and port.

Get the API version

Cchar *api_version = rm_api_version(); printf("API Version: %s.\n", api_version);Get and display the API version.

Configure ModbusRTU mode.

Crm_set_modbus_mode(robot_handle, 0, 115200, 10);Write single coil data

Crm_peripheral_read_write_params_t write_params = {0, 0, 2, 1}; result = rm_write_single_coil(robot_handle, write_params, 1);Read single coil data

Crm_peripheral_read_write_params_t read_params = {0, 0, 2, 1}; int coil_data; result = rm_read_coils(robot_handle, read_params, &coil_data);Write a single register

Crm_peripheral_read_write_params_t write_single_register_params = { 0, 0, 2, 1}; result = rm_write_single_register(robot_handle, write_single_register_params, 180); if (check_result(result, "Failed to write single register") != 0) { return -1; }Read holding registers

Crm_peripheral_read_write_params_t holding_registers_params = {0, 0, 2, 1}; int holding_register_data; result = rm_read_holding_registers(robot_handle, holding_registers_params, &holding_register_data);Close ModbusRTU mode

Crm_close_modbus_mode(robot_handle, 0);Disconnect from the robotic arm

Crm_delete_robot_arm(robot_handle);

6. License information

- This project is subject to the MIT license.

Controller and End Interface Diagram

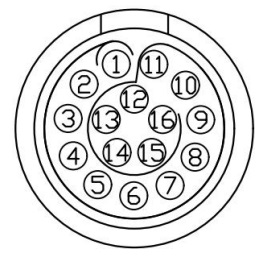

Controller IO Interface Diagram

The definitions of wires are explained in the following Table.

| No. | First-generation cable wiring sequence | Second-generation cable wiring sequence | Definition | Description | Wire number (for second-generation cables only) | Remarks |

|---|---|---|---|---|---|---|

| 1 | Pink and brown | Black stripe brown/brown | VOUT | External output + | NO.1 | 12 V/24 V |

| 2 | Gray and purple | Gray/purple | P_IO_GND | External output - | NO.2 | |

| 3 | Yellow | Yellow | 485A | NO.3 | ||

| 4 | Yellow and green | Black stripe yellow | 485B | NO.4 | ||

| 5 | Purple and white | Black stripe white | IO1 | Igital input/output bidirectional channel | NO.5 | |

| 6 | Red and white | White stripe red | IO2 | Igital input/output bidirectional channel | NO.6 | |

| 7 | Green and white | Black stripe green | IO3 | Igital input/output bidirectional channel | NO.7 | |

| 8 | Yellow and white | White stripe black | IO4 | Igital input/output bidirectional channel | NO.8 | |

| 9 | Blue and white | Black stripe orange | OUT_P_IN | Digital power supply for external input | NO.9 | 0−24 V |

| 10 | Light blue | Black stripe blue | OUT_P_OUT | Digital power supply for external output | NO.10 | 0−24 V |

| 11 | Deep blue | Blue | OUT_P_GND | External digital ground | NO.11 | |

| 12 | Green | Green | FDCAN_A | CAN_H | NO.12 | |

| 13 | Red | Red | FDCAN_B | CAN_L | NO.13 | |

| 14 | White | White | Blank | Reserved | NO.14 | |

| 15 | Black | Black | Blank | Reserved | NO.15 | |

| 16 | Orange | Orange | Blank | Reserved | NO.16 |

Note

The voltage of digital I/O is determined based on the reference voltage connected, and the 16-core extension interface cable of robotic arm provides only 12 V and 24 V power supply voltages. If other output voltages are required for the digital I/O, then reference voltages need to be led in from the pins OUT_P_OUT+, OUT_P_IN+, and OUT_P_GND.

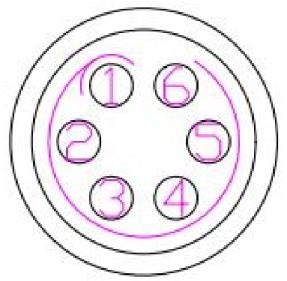

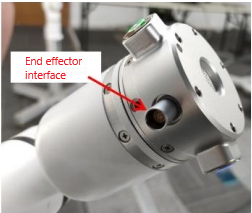

End Effector IO Interface Diagram

The end-effector tool IO interface connects external tools through a 6-core aerial plug. The pins and definitions of the aerial plug are as follows.

| Pin No. | Wiring color | Function |

|---|---|---|

| 1 | Yellow | RS485_A |

| 2 | White | RS485_B |

| 3 | Red | Digital interface 1 (DI1/DO1) |

| 4 | Black | Digital interface 2 (DI2/DO2) |

| 5 | Green | Power GND |

| 6 | Blue | Power output: 0 V/12 V/24 V, controllable by program |

Note

The multiplexing functions in the table above are switched by program commands. Pin 3 and pin 4 are digital input channels (DI1 and DI2) by default before delivery, and the power output of pin 6 is 0 V (programmed).

End IO Interface Diagram

Simulated ModRTU Diagram