Demo演示(C、C++):

ModbusRTU模式使用示例 1. 项目介绍

本项目演示如何配置RS485端口为ModbusRTU模式,并通过接口与连接的外设进行读写操作,示例操作流程如下:

完成配置通讯端口ModbusRTU模式、写单圈数据、读单圈数据、写单个寄存器、读保存寄存器、关闭通讯端口 Modbus RTU 模式。

项目基于Cmake构建,使用了睿尔曼提供的机械臂C语言开发包。

2. 代码结构

RMDemo_ModbusRTU

├── build # CMake构建生成的输出目录(如Makefile、构建文件等)

├── include # 自定义头文件存放目录

├── Robotic_Arm # 睿尔曼机械臂二次开发包

│ ├── include

│ │ ├── rm_define.h # 机械臂二次开发包头文件,包含了定义的数据类型、结构体

│ │ └── rm_interface.h # 机械臂二次开发包头文件,声明了机械臂所有操作接口

│ └── lib

│ ├── api_c.dll # Windows 64bit 的 API 库

│ ├── api_c.lib # Windows 64bit 的 API 库

│ └── libapi_c.so # Linux x86 的 API 库

├── src

│ └── main.c # 主函数

├── CMakeLists.txt # 项目的顶层CMake配置文件

├── readme.md # 项目说明文档

├── run.bat # Windows快速运行脚本

└── run.sh # linux快速运行脚本3.项目下载

通过链接下载 RM_API2 到本地:开发包下载,进入RM_API2\Demo\RMDemo_C目录,可找到RMDemo_ModbusRTU。

4. 环境配置

在Windows和Linux环境下运行时需要的环境和依赖项:

| 项目 | Linux | Windows |

|---|---|---|

| 系统架构 | x86架构 | - |

| 编译器 | GCC 7.5或更高版本 | MSVC2015或更高版本 64bit |

| CMake版本 | 3.10或更高版本 | 3.10或更高版本 |

| 特定依赖 | RMAPI Linux版本库(位于Robotic_Arm/lib目录) | RMAPI Windows版本库(位于Robotic_Arm/lib目录) |

Linux环境配置

1. 编译器(GCC) 在大多数Linux发行版中,GCC是默认安装的,但可能版本不是最新的。如果需要安装特定版本的GCC(如7.5或更高版本),可以使用包管理器进行安装。以Ubuntu为例,可以使用以下命令安装或更新GCC:

# 检查GCC版本

gcc --version

sudo apt update

sudo apt install gcc-7 g++-7注意:如果系统默认安装的GCC版本已满足或高于要求,则无需进行额外安装。

2. CMake CMake在大多数Linux发行版中也可以通过包管理器安装。以Ubuntu为例:

sudo apt update

sudo apt install cmake

# 检查CMake版本

cmake --versionWindows环境配置

1. 编译器(MSVC2015或更高版本) MSVC(Microsoft Visual C++)编译器通常随Visual Studio一起安装。可以按照以下步骤安装:

- 访问Visual Studio官网下载并安装Visual Studio。

- 在安装过程中,选择“使用C++的桌面开发”工作负载,这将包括MSVC编译器。

- 根据需要选择其他组件,如CMake(如果尚未安装)。

- 完成安装后,打开Visual Studio命令提示符(可在开始菜单中找到),输入

cl命令检查MSVC编译器是否安装成功。

2. CMake 如果Visual Studio安装过程中未包含CMake,可以单独下载并安装CMake。

- 访问CMake官网下载适用于Windows的安装程序。

- 运行安装程序,按照提示进行安装。

- 安装完成后,将CMake的bin目录添加到系统的PATH环境变量中(通常在安装过程中会询问是否添加)。

- 打开命令提示符或PowerShell,输入

cmake --version检查CMake是否安装成功。

5. 使用指南

5.1 快速运行

按照以下步骤快速运行代码:

配置机械臂IP地址: 打开

main.c文件,在main函数中修改robot_ip_address参数为当前机械臂的IP地址,默认IP地址为"192.168.1.18"。Cconst char *robot_ip_address = "192.168.1.18"; int robot_port = 8080; rm_robot_handle *robot_handle = rm_create_robot_arm(robot_ip_address, robot_port);linux 命令行运行: 在终端进入

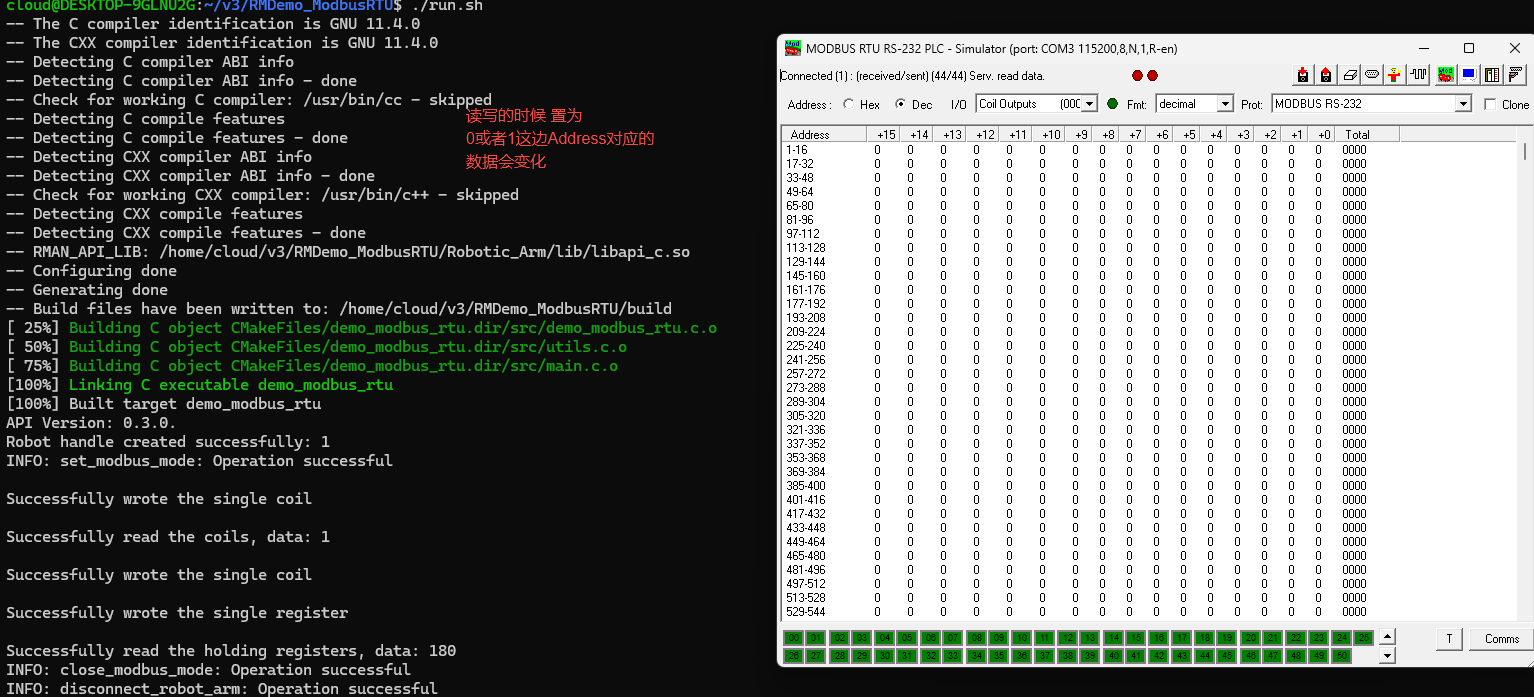

RMDemo_ModbusRTU目录,输入以下命令运行C程序:bashchmod +x run.sh ./run.sh运行结果如下:

参考 Windows 的运行结果。

Windows 运行: 双击run.bat脚本运行 运行结果如下:

Run...

API Version: 1.0.0.

send is: {"command":"get_arm_software_info"}

thread_socket_receive len 315 robot_handle: 1 message:{"Product_version":"RM65-BI","algorithm_info":{"version":"1.4.4"},"command":"arm_software_info","ctrl_info":{"build_time":"2024/08/28 18:36:18","commit_id":"0315333","version":"V1.6.1"},"dynamic_info":{"model_version":"2"},"plan_info":{"build_time":"2024/08/28 18:36:33","commit_id":"166c4a8","version":"V1.6.1"}}

[rm_get_arm_software_info] Product version: RM65-BI

[rm_get_arm_software_info] Algorithm version: 1.4.4

[rm_get_arm_software_info] Ctrl version: V1.6.1

[rm_get_arm_software_info] Ctrl build Time: 2024/08/28 18:36:18

[rm_get_arm_software_info] Dynamic model version: 2

[rm_get_arm_software_info] Plan version: V1.6.1

[rm_get_arm_software_info] Plan build Time: 2024/08/28 18:36:18

send is: {"command":"get_realtime_push"}

thread_socket_receive len 195 robot_handle: 1 message:{"command":"get_realtime_push","custom":{"expand_state":false,"joint_acc":false,"joint_speed":false,"lift_state":false,"tail_end":false},"cycle":5,"enable":true,"ip":"192.168.1.88","port":8089}

[rm_get_realtime_push] cycle parse result: 5

[rm_get_realtime_push] port parse result: 8089

[rm_get_realtime_push] ip parse result: 192.168.1.88

[rm_get_realtime_push] enable parse result: 1

send is: {"command":"get_current_work_frame"}

thread_socket_receive len 74 robot_handle: 1 message:{"frame_name":"World","pose":[0,0,0,0,0,0],"state":"current_work_frame"}

[get_current_work_frame] Work frame Name: World

[get_current_work_frame] Work frame pose: (0.000, 0.000, 0.000, 0.000, 0.000, 0.000)

send is: {"command":"get_current_tool_frame"}

thread_socket_receive len 106 robot_handle: 1 message:{"payload":0,"pose":[0,0,0,0,0,0],"position":[0,0,0],"state":"current_tool_frame","tool_name":"Arm_Tip"}

[get_current_tool_frame] Tool frame Name: Arm_Tip

[get_current_tool_frame] Tool frame pose: (0.000, 0.000, 0.000, 0.000, 0.000, 0.000)

[get_current_tool_frame] Tool frame payloda: 0.000

[get_current_tool_frame] Tool frame position: (0.000, 0.000, 0.000)

send is: {"command":"get_install_pose"}

thread_socket_receive len 41 robot_handle: 1 message:{"pose":[0,0,0],"state":"install_pose"}

[rm_get_install_pose] pose parse result:

0

0

0

send is: {"command":"get_joint_min_pos"}

thread_socket_receive len 87 robot_handle: 1 message:{"min_pos":[-178000,-130000,-135000,-178000,-128000,-360000],"state":"joint_min_pos"}

[rm_get_joint_min_pos] min_pos parse result:

-178000

-130000

-135000

-178000

-128000

-360000

send is: {"command":"get_joint_max_pos"}

thread_socket_receive len 81 robot_handle: 1 message:{"max_pos":[178000,130000,135000,178000,128000,360000],"state":"joint_max_pos"}

[rm_get_joint_max_pos] max_pos parse result:

178000

130000

135000

178000

128000

360000

send is: {"command":"get_joint_max_acc"}

thread_socket_receive len 83 robot_handle: 1 message:{"joint_acc":[100000,100000,100000,100000,100000,100000],"state":"joint_max_acc"}

[rm_get_joint_max_acc] joint_acc parse result:

100000

100000

100000

100000

100000

100000

send is: {"command":"get_joint_max_speed"}

thread_socket_receive len 81 robot_handle: 1 message:{"joint_speed":[30000,30000,37500,37500,37500,37500],"state":"joint_max_speed"}

[rm_get_joint_max_speed] joint_speed parse result:

30000

30000

37500

37500

37500

37500

Robot handle created successfully: 1

send is: {"command":"set_modbus_mode","port":0,"baudrate":115200,"timeout":10}

thread_socket_receive len 48 robot_handle: 1 message:{"command":"set_modbus_mode","set_state":true}

[rm_set_modbus_mode] set_state: true

send is: {"command":"write_single_coil","port":0,"address":0,"data":0,"device":2}

thread_socket_receive len 52 robot_handle: 1 message:{"command":"write_single_coil","write_state":true}

[rm_write_single_coil] write_state: true

send is: {"command":"read_coils","port":0,"address":0,"num":1,"device":2}

thread_socket_receive len 35 robot_handle: 1 message:{"command":"read_coils","data":0}

[rm_read_coils] data parse result: 0

send is: {"command":"write_single_coil","port":0,"address":0,"data":1,"device":2}

thread_socket_receive len 52 robot_handle: 1 message:{"command":"write_single_coil","write_state":true}

[rm_write_single_coil] write_state: true

send is: {"command":"write_single_register","port":0,"address":0,"data":180,"device":2}

thread_socket_receive len 56 robot_handle: 1 message:{"command":"write_single_register","write_state":true}

[rm_write_single_register] write_state: true

send is: {"command":"read_holding_registers","port":0,"address":0,"device":2}

thread_socket_receive len 49 robot_handle: 1 message:{"command":"read_holding_registers","data":180}

[rm_read_holding_registers] data parse result: 180

send is: {"command":"close_modbus_mode","port":0}

thread_socket_receive len 50 robot_handle: 1 message:{"command":"close_modbus_mode","set_state":true}

[rm_close_modbus_mode] set_state: true

请按任意键继续...5.2 关键代码说明

下面是 main.c 文件的主要功能:

连接机械臂

Crm_robot_handle *robot_handle = rm_create_robot_arm(robot_ip_address, robot_port);连接到指定IP和端口的机械臂。

获取API版本

Cchar *api_version = rm_api_version(); printf("API Version: %s.\n", api_version);获取并显示API版本。

配置Modbus RTU模式

Crm_set_modbus_mode(robot_handle, 0, 115200, 10);写单圈数据

Crm_peripheral_read_write_params_t write_params = {0, 0, 2, 1}; result = rm_write_single_coil(robot_handle, write_params, 1);读单圈数据

Crm_peripheral_read_write_params_t read_params = {0, 0, 2, 1}; int coil_data; result = rm_read_coils(robot_handle, read_params, &coil_data);写单个寄存器

Crm_peripheral_read_write_params_t write_single_register_params = { 0, 0, 2, 1}; result = rm_write_single_register(robot_handle, write_single_register_params, 180); if (check_result(result, "Failed to write single register") != 0) { return -1; }读保存寄存器

Crm_peripheral_read_write_params_t holding_registers_params = {0, 0, 2, 1}; int holding_register_data; result = rm_read_holding_registers(robot_handle, holding_registers_params, &holding_register_data);关闭Modbus RTU模式

Crm_close_modbus_mode(robot_handle, 0);断开机械臂连接

Crm_delete_robot_arm(robot_handle);

6. 许可证信息

- 本项目遵循MIT许可证。

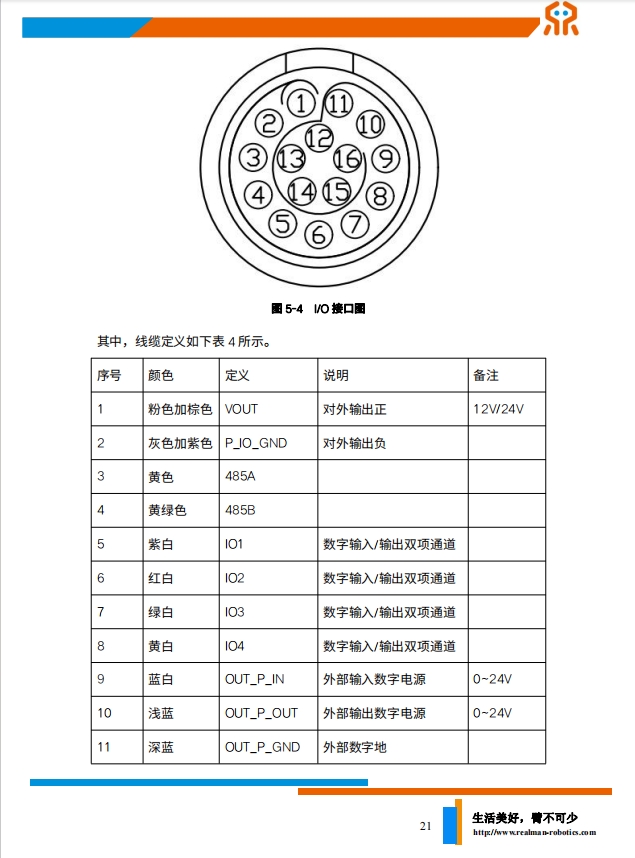

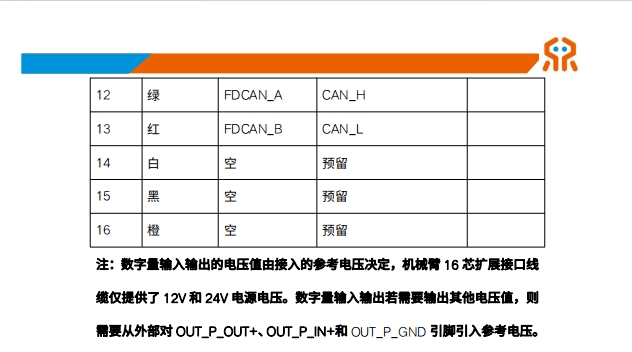

控制器和终端接口图

控制器 IO 接口图 1

控制器 IO 接口图 2

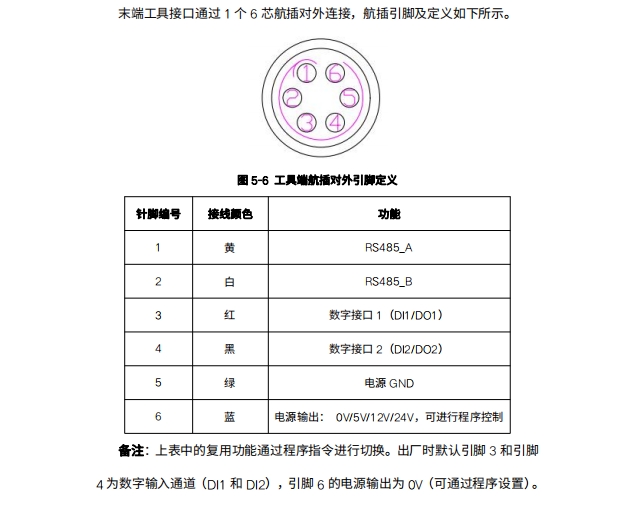

终端 IO 接口图

终端 IO 接口图

模拟ModRTU图